Home Technology

Phased array ultrasonics (PA) is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. Common applications are to non invasively examine the heart or to find flaws in manufactured materials such as welds.

Learn More

Although time-of-flight diffraction (TOFD) can be used for a variety of applications, its primary use is rapid weld testing of circumferential and axial weld seams, also known as perpendicular TOFD scanning.

Learn More

Magnetic flux leakage (MFL) is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel.

Learn More

Ultrasonic Inspection is a very useful and versatile NDT method. It is sensitive to both surface and subsurface discontinuities. It has other uses, such as thickness measurement, in addition to flaw detection.

Learn More

Steel rods and Pipes are inspected for surface and sub-surface Cracks and Defects before machining to reduce production loss. Whether manual, automated, or phased array, ultrasonic testing can help manufacturers of bars.

Learn More

Ultrasonic Testing (UT) of steel forgings is a non-destructive method used to detect internal defects, such as cracks, inclusions, and voids. High-frequency sound waves are introduced into the forging, and reflected signals are analyzed to identify.

Learn More

Condenser Leak Testing is used to detect leaks in condenser systems, ensuring efficient operation and preventing damage. Common methods include hydrostatic, air pressure, vacuum, and helium testing for precise leak identification..

Learn More

Cryogenic and Low-Temperature Testing evaluates material and equipment performance under extreme cold conditions to ensure reliability and safety. It is crucial for industries like aerospace, LNG, and cryogenic storage, simulating temperatures as low as -196°C.

Learn More

Fugitive Emission Testing identifies leaks of gases or vapors from pressurized equipment, such as valves and flanges, to reduce environmental impact and ensure safety. Common methods include infrared imaging, flame ionization detection (FID), and EPA Method 21 compliance testing.

Learn More

Condenser Air Ingress Testing detects unwanted air entry into a condenser system, which can reduce efficiency and increase operational costs. Common methods include helium tracer gas testing and vacuum monitoring to identify.

Learn More

Helium Leak Testing is a precise method for detecting leaks using helium as a tracer gas due to its small atomic size and low viscosity. It involves introducing helium into the system and using a mass spectrometer or detector to locate and quantify leaks

Learn More

Automatic Eddy Current Sorter is a non-destructive testing system used to inspect and sort components based on material properties or defects. It utilizes eddy current sensors to detect variations in conductivity, permeability, or surface cracks, ensuring fast and accurate sorting for quality control in industries like automotive, aerospace, and manufacturing

Learn More

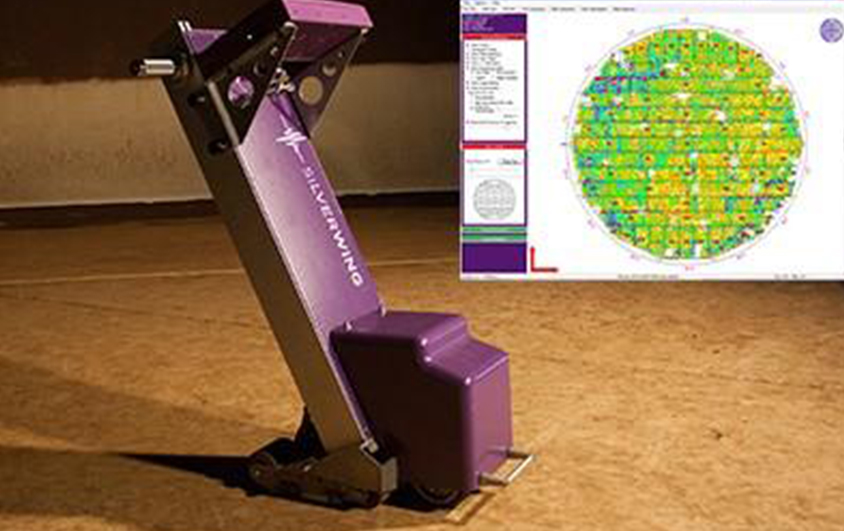

Corrosion Mapping is a non-destructive technique used to identify and quantify corrosion in structures like pipelines, tanks, and vessels. It provides detailed visual data on wall thickness and corrosion severity, aiding in maintenance planning and ensuring structural integrity.

Learn More

Pipeline Thickness Gauging is a non-destructive testing method used to measure the wall thickness of pipelines, helping to detect corrosion, wear, or other forms of degradation. Techniques like ultrasonic testing (UT) are commonly used to assess thickness and ensure the pipeline's structural integrity and safety

Learn More

Boiler Tube Thickness Survey is a non-destructive testing method used to measure the wall thickness of boiler tubes to assess their condition and identify signs of corrosion, erosion, or wear. Techniques like ultrasonic testing (UT) or eddy current testing are commonly employed to ensure the integrity and safe operation of boiler systems

Learn More

In-situ Oxide Scale Thickness Measurement is a non-destructive technique used to measure the thickness of oxide layers formed on metal surfaces, typically in high-temperature environments like boilers, turbines, and reactors. Methods such as ultrasonic testing or eddy current testing are used to assess the oxide scale without removing the material, helping to prevent premature failure and optimize maintenance schedules

Learn More

Eddy Current Tube Inspection is a non-destructive testing method used to detect defects such as cracks, corrosion, and wear in metallic tubes. By inducing eddy currents in the tube material and analyzing the resulting electromagnetic fields, this technique identifies surface and near-surface flaws, commonly used in heat exchangers, boilers, and condenser tubes for quality control and maintenance

Learn More