Home Application

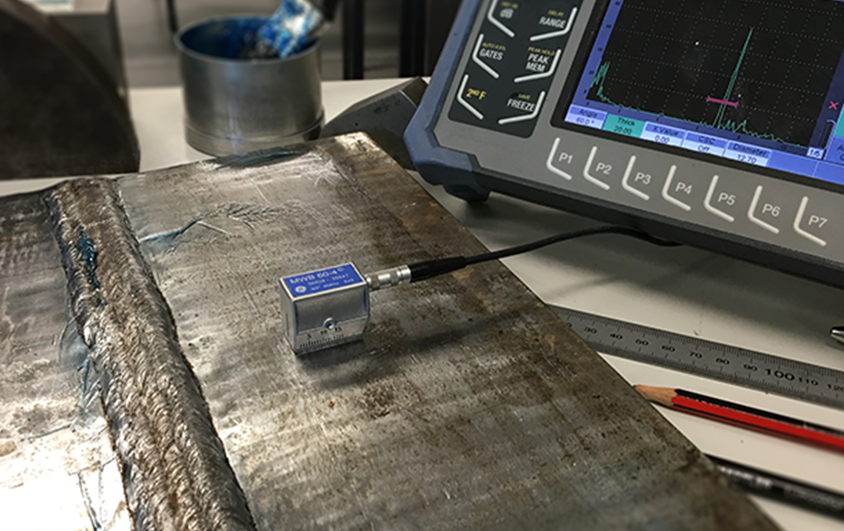

Ultrasonic Testing (UT) Weld Inspection is a non-destructive method used to detect internal and surface defects in welded joints. High-frequency sound waves are sent through the weld to identify flaws such as cracks, porosity, or inclusions. This technique is essential for ensuring the structural integrity and safety of critical welds in industries like construction, aerospace, and manufacturing.

Dye Penetrant Weld Inspection is a non-destructive testing method used to detect surface-breaking defects in welded joints. A liquid dye is applied to the surface, which penetrates any cracks or voids, and then excess dye is removed. A developer is applied to draw out the penetrant, revealing the defects under UV or visible light. This method is widely used

Eddy Current Weld Inspection detects surface and near-surface defects in welded joints using induced electromagnetic fields. The technique identifies flaws like cracks, porosity, or inclusions by analyzing changes in the eddy current response. It is widely used for inspecting welds in materials like steel and aluminum, providing fast.

Phased array ultrasonics (PA) is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. Common applications are to non invasively examine the heart or to find flaws in manufactured materials such as welds

Ultrasonic Inspection is a very useful and versatile NDT method. It is sensitive to both surface and subsurface discontinuities. It has other uses, such as thickness measurement, in addition to flaw detection.

Steel rods and Pipes are inspected for surface and sub-surface Cracks and Defects before machining to reduce production loss. Whether manual, automated.

Pipeline Thickness Gauging is a non-destructive testing method used to measure the wall thickness of pipelines to detect corrosion, erosion, or wear. Techniques like ultrasonic testing (UT) are commonly employed.

Eddy Current Tube Inspection is a non-destructive testing method used to detect defects such as cracks, corrosion, and wear in metallic tubes. By inducing eddy currents in the tube material and analyzing the resulting electromagnetic.

Remote field testing (RFT) is an electromagnetic method of non-destructive testing whose main application is finding defects in steel pipes and tubes. RFT may also be referred to as RFEC (remote field eddy current) or RFET (remote field eddy current technique)

The internal rotary inspection system (IRIS) is an ultrasonic non-destructive testing (NDT) technique used to inspect pipes and tubes

Condenser Leak Testing is used to detect leaks in condenser systems, ensuring efficient operation and preventing damage. Common methods include hydrostatic, air pressure, vacuum, and helium testing for precise leak identification..

Cryogenic and Low-Temperature Testing evaluates material and equipment performance under extreme cold conditions to ensure reliability and safety. It is crucial for industries like aerospace, LNG, and cryogenic storage, simulating temperatures as low as -196°C.

Fugitive Emission Testing identifies leaks of gases or vapors from pressurized equipment, such as valves and flanges, to reduce environmental impact and ensure safety. Common methods include infrared imaging, flame ionization detection (FID), and EPA Method 21 compliance testing.

Condenser Air Ingress Testing detects unwanted air entry into a condenser system, which can reduce efficiency and increase operational costs. Common methods include helium tracer gas testing and vacuum monitoring to identify and seal leaks effectively

Helium Leak Testing is a precise method for detecting leaks using helium as a tracer gas due to its small atomic size and low viscosity. It involves introducing helium into the system and using a mass spectrometer or detector to locate and quantify leaks

Corrosion Mapping is a non-destructive technique used to identify and quantify corrosion in structures like pipelines, tanks, and vessels. It provides detailed visual data on wall thickness and corrosion severity, aiding in maintenance planning and ensuring structural integrity.

Pipeline Thickness Gauging is a non-destructive testing method used to measure the wall thickness of pipelines, helping to detect corrosion, wear, or other forms of degradation. Techniques like ultrasonic testing (UT) are commonly used to assess thickness and ensure the pipeline's structural integrity and safety

Boiler Tube Thickness Survey is a non-destructive testing method used to measure the wall thickness of boiler tubes to assess their condition and identify signs of corrosion, erosion, or wear. Techniques like ultrasonic testing (UT) or eddy current.

Forgings are used where High Strength material component is required such as Generator Shafts. These forged materials when manufactured are subjected to Heat and Compression to attain the required Strength and Shape.